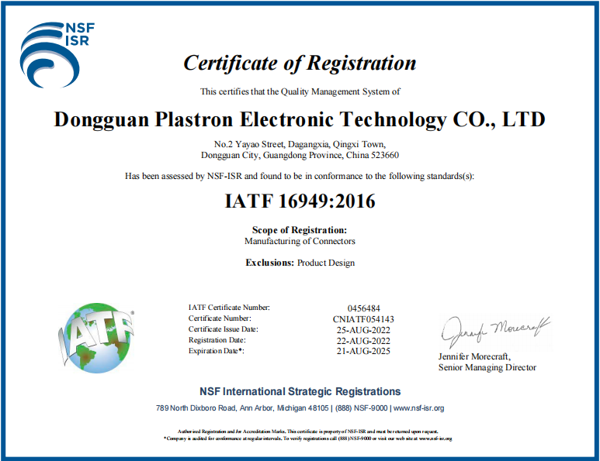

Plastron had got the ISO16949:2016 certificate since Aug. 2022.

Origin of IS0/TS16949:

As one of the two major bases of automobile production, the three major American automobile companies (General Motors, Ford and Chrysler) began to adopt QS-9000 as a unified quality management system standard for their suppliers in 1994. At the same time, another production base, Europe, especially Germany, has issued corresponding quality management system standards, such as VDA6.1, AVSQ94, EAQF, etc. Because the United States or European auto parts suppliers at the same time to provide products to the major Oems, which requires it must meet both QS-9000, and to meet such as VDA6.1, resulting in the repeated certification of different standards of the suppliers, which urgently requires the introduction of a set of international general automotive industry quality system standards, in order to meet the requirements of the major Oems at the same time, ISO16949:2009 came into being.

ISO/TS 16949 technical specification is the international automotive task force (ATF) and the International Organization for Standardization quality management and quality assurance technical committee (1SO/TC176) in order to meet the needs of the automotive industry global procurement, Reduce parts and materials suppliers in order to meet the quality system requirements of various countries and multiple certification burden, reduce procurement costs, and on the basis of I09000 quality management system standards, developed Technical Specification, its full name is “quality system – automotive suppliers quality management system requirements”

ISO/TS16949 goal?

1. Continuous improvement in the enterprise and suppliers: including quality improvement, productivity improvement, so as to reduce costs.

2, emphasis on the prevention of shortcomings: the use of SPC technology and error prevention measures, to prevent the occurrence of unqualified, “the first time to do well” is the most economic quality cost.

3. Reduce variation and waste: ensure inventory turnover and minimum inventory, emphasize quality cost, control non-quality additional costs (such as waiting time, excessive handling, etc.).

4. Focus on process: It is not only necessary to manage the process results, but also to control the process itself, so as to effectively use resources, reduce costs and shorten the cycle.

5, pay attention to customer expectations: all kinds of technical standards can only be qualified and unqualified criteria, but not qualified products can produce benefits, only let the user is completely satisfied with the product can be received by customers, in order to create value, so the ultimate standard of quality is user satisfaction, user satisfaction is the best way to achieve quality.

Post time: Mar-07-2023