HDMI Connector

HDMI CONNECTOR

● Product Specifications

| Current Rating: | 0.5 A | |||||||||

| Voltage Rating: | AC 40 V | |||||||||

| Contact Resistance: | 10mΩMax.(Excluding conductor resistance) | |||||||||

| Operating Temperature: | -20℃~+85℃ | |||||||||

| Insulation Resistance: | 100MΩ | |||||||||

| Withstanding Voltage | 500V AC/60S | |||||||||

| Max.Processing Temperature: | 260℃ for 10 Seconds | |||||||||

| Contact Material: | Copper Alloy | |||||||||

| Housing Material: | High Temperature Thermoplastic.UL 94V-0 | |||||||||

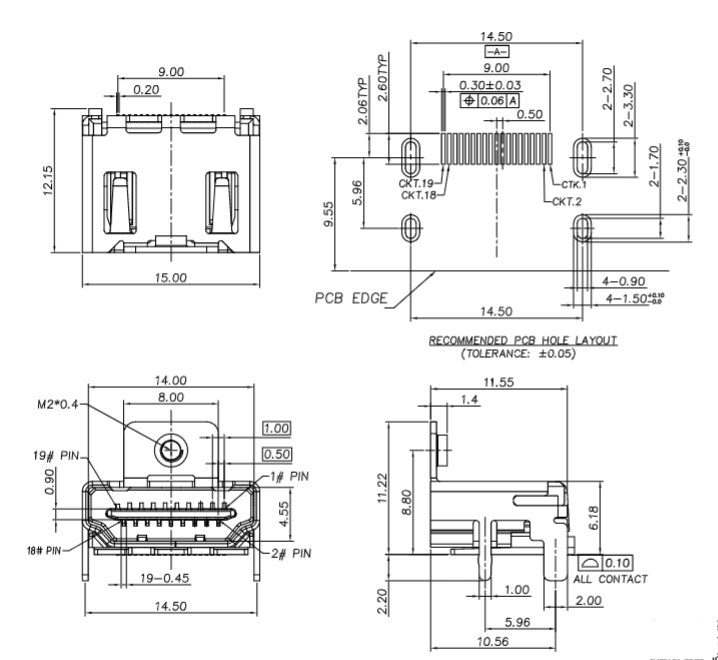

● Dimensional Drawings

Contact us to get more of our HDMI drawings

● Scope

1.1.CONTENTS

The specification covers performance,tests and quality requirements for Mini HDMI connector.(C TYPE)

1.2.QUALIFICATION

Tests are to be performed by the procedures stated in this specification,All inspections shall be conducted using the inspections plan for this product and product drawing.

● APPLICABLE DOCUMENTS

Unless otherwise specified,the latest edition of the document applies. In the event ofconflict between the requirements of this specification and the product drawing, the product drawing shall take precedence.In the event of conflict between the requirements of this specification and the referenced documents,this specification shall take precedence.

● REQUIREMENTS

3.1.DESIGN AND CONSTRUCTION

Product shall be of the design,construction and physical dimensions specified on the applicable product drawing.

3.2.MATERIALS

A.Housing:Thermoplastic Plastic,UL94V-0,Color:Black

B.Contact:Copper Alloy,

Finish: Ni underplated overall,Au plating on contact area, Tin Plating on Solder Tail

C.Shell: Copper alloy

Finish: Nickel Plating over all

3.3.RATINGS

A.Voltage Rating: 40V AC MAX.

B.Operating temperature: -250C to +850C

C.Current Rating: 0.5A Min(per pin)

● PERFORMANCE REQUIREMENT AND TEST PROCEDURES

| TEST ITEM | REQUIREMENT | TEST CONDITION | |||||||||

| Examination of product | Meet the requirements of product drawing.No physical damage. | Visual inspection | |||||||||

| ELECTRICAL PERFORMANCE | |||||||||||

| Contact Resistance | Contact:10mΩ Max.initial (Excluding condutor resistance) Shell:10mΩ Max.initial (Excluding condutor resistance) | Mated connector, Contacts:measure by dry circuit,20mV Max,10mA.(EIA-364-23) Shell:measure by dry circuit,5V Max,100mA.(EIA-364-6A) | |||||||||

| Dielectric withstanding Voltage | No breakdown | Unmated connector,apply 500V AC(rms) for 1 minute between adjacent terminal or ground.Mated connector,apply 300V AC(rms) for 1 minute between adjacent terminal or ground.(EIA-364-20) | |||||||||

| Insulation Resistance | 100MΩ Min(Unated), 10MΩ Min(Mated) | Unmated connector,apply 500V DC between adjacent terminal or ground. Mated connector,apply 150V DC between adjacent terminal or ground.(EIA-364-21) | |||||||||

| MECHANICAL PERFORMANCE | |||||||||||

| Mating force | 44.1N Max. | Operation speed:25±3mm/min. Measure the force required to mate connector. (EIA-364-13) | |||||||||

| Unmating force | 7 N Min. 25N Max. | Operation speed:25±3mm/min. Measure the force required to unmated connector. (EIA-364-13) | |||||||||

| Durability | Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Number of cycles:5,000 cycles at 100±50 cycles per hour. | |||||||||

| Vibration | Appearance:no damage Discontinuity:1 microsecond Max. Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Amplitude: 1.52mm P-P or 147m/s2{15G} Sweep time: 50-2000-50 Hz in 20minutes. Duration:12times in each (total of 36times) X,Y and Z axes. Electrical load:DC 100mA current shall be flowed during the test. (EIA-364-28 Condition III Method 5A) | |||||||||

| Mechanical Shock | Appearance:no damage Discontinuity:1 microsecond Max. Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Pulse width : 11msec Wave form : half sine 490m/s2{50G} 3 strokes in X,Y and Z axes. (EIA-364-27 Condition A) | |||||||||

| Cable Flexing | Appearance:no damage Discontinuity:1 microsecond Max. | 100cycles in each of 2 planes Dimension X=3.7x cable diameter (EIA-364-41C,Condition I) | |||||||||

| ENVIRONMENTAL PERFORMANCE | |||||||||||

| Thermal Shock | Appearance:no damage Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Mated Connectors and subject to the following Conditions for 10 cycles. a)-55±30C(30 minutes) b)+85±30C(30 minutes) (Transit time shall be within 3 minutes) (EIA-364-32C,Condition I) | |||||||||

| Humidity | A | Appearance:no damage. Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Mated connectors. +250C ~ +850C with 80~95% R.H.for 96 hours (4cycles). Upon completion of the test specimens shall be conditioned at ambient room conditions for 24 hours,after which the specified measurements shall be performed (EIA-364-31B) | ||||||||

| B | Appearance:no damage. Dielectric Withsanding Voltage: must meet requirement Insulation Resistance: mustmeet requirement. | Unmated connectors. +250C ~ +850C with 80~95% R.H.for 96 hours (4cycles). Upon completion of the test specimens shall be conditioned at ambient room conditions for 24 hours,after which the specified measurements shall be performed (EIA-364-31B) | |||||||||

| Thermal Aging | Appearance: no damage. Contact Resistance: Contact: Change from initial vaule:30mΩMax. Shell: Change from initial vaule:50mΩMax. | Mated connectors and expose to +105±20C for 250 hours.Upon completion of the exposure period,the test specimens shall be conditioned at ambient room condition for 1to2 hours,after which the specified measurements shall be performed. (EIA-364-17B,condition4,method A) | |||||||||